Designer Christian Tse is working to perfect this promising production method for precious metals.

When award-winning jewelry designer and manufacturer Christian Tse first dabbled in 3D printing in 2001, the technology’s capabilities were rudimentary. Tse saw potential, though, and eventually sought to collaborate with US-based 3D printing company Desktop Metal to develop a precious-metal printer for fine jewelry. The result was the Production System P-1, which debuted to the trade in 2022 alongside Tse’s precious-metal print powders in silver, gold, platinum, and rose gold.

Problem solving

The P-1 addresses some of the toughest jewelry-manufacturing issues. It combats metal porosity by applying high pressure and high heat to the material, making finished pieces denser and shinier than traditionally-made jewels. The P-1 also cuts down on production time and costs compared to rival precious-metal 3D printers, Tse says.

“The competition’s footprint is about a glass of water in size compared to our shoebox size,” he explains. “Meaning, if you printed the contents of their glass, it would take 40 hours, versus printing the contents of our shoebox, which takes 11 hours.”

In addition, the machine can eliminate shipping delays and customs fees (for now), because if a manufacturer has the P-1, the designer can simply email that client the files for production. This move skips the steps of producing cast models overseas and shipping them to the client for finishing; the whole production and manufacturing process can take place wherever the P-1 model is located.

Still, P-1 technology “isn’t 100% consistent,” cautions Tse; it needs refinement before it’s ready for sale. The device also has a larger sibling in Desktop Metal’s P-50 model, which is for mass production and still needs refinements of its own. A high-profile brand that’s working with Tse is eager for an advanced model. “We are designing around their specifications and hope to unveil that project by late 2023,” he says.

Extra hands

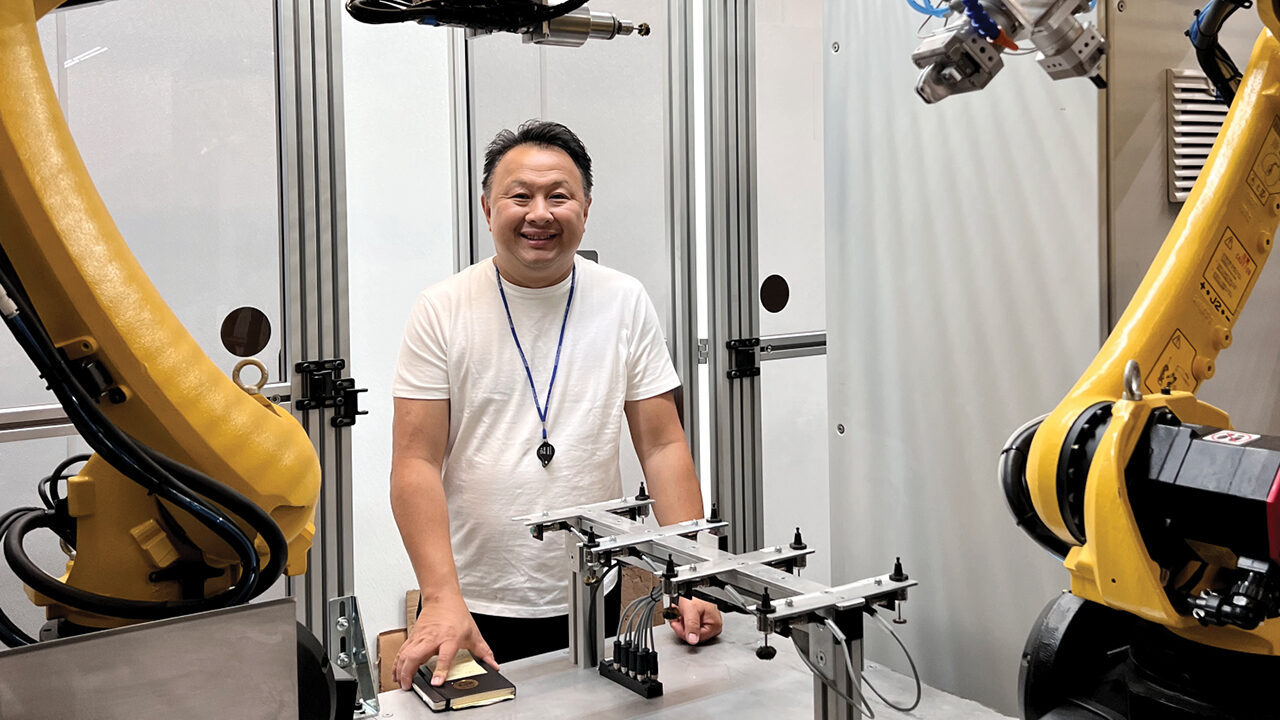

When Tse’s perfected 3D printers arrive on the scene, they’ll have company: He’s already working with the VDK-2300 automated polishing system by Flexible Robotic Environment. The giant robotic polishing arms, which Tse has customized for jewelry, help address the shortage of skilled craftsmen. “These robot arms work in tandem, moving in nine different positions, to polish every angle of a piece,” he says. “Overnight, a robot can polish 100 units, and in the morning, one of our skilled polishers comes in and completes the job by spending a few minutes on each ring. So it’s not a magic bullet, but it does help.”

Image: Christian Tse stands beside his robotic polishing system. (Christian Tse)